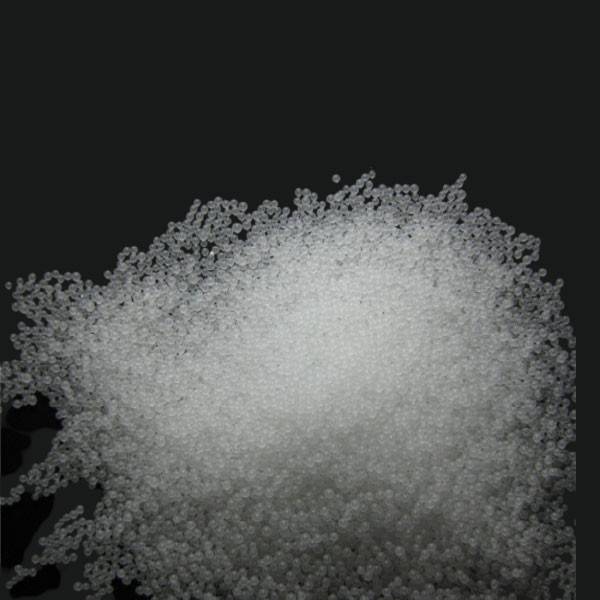

New Arrival China Raw Polystyrene Beads - EPS raw materials – Xiongye

New Arrival China Raw Polystyrene Beads - EPS raw materials – Xiongye Detail:

E.P.S. (Expandable Poly Styrene) is a lightweight, rigid, plastic foam insulation material produced from solid particles of polystyrene. Expansion is achieved by virtue of small amounts of pentane gas dissolved into the polystyrene base material during production. The gas expands under the action of heat, applied as steam, to form perfectly closed cells of EPS. These cells occupy approximately 40 times the volume of the original polystyrene bead. The EPS beads are then molded into appropriate forms suited to their application. Products made from foamed polystyrene are nearly ubiquitous, for example packing materials, insulation, and foam drink cups

Ⅰ.E grade EPS raw materials:

E-standard grade material is a widely used ordinary EPS, suitable for automatic vacuum forming machines, electric drive forming machines, and traditional lifting hydraulic presses. It is a standard foaming ratio raw material, which can be foamed to achieve lighter density foams at a time. Generally, it is more suitable for products with a foaming rate of 13 g/l or more. It is widely used in electrical packaging, thermal insulation materials, and fishing floats. , Handicrafts, decorations, lost foam castings, etc.

Product Features:

1. Fast foaming speed;

2. Standard foaming ratio (the ratio is lower than P material);

3. Low energy consumption and steam saving;

4. Short curing time and molding cycle;

5. The product has good sinterability;

6. Smooth surface;

7. The size is stable, the strength is high, the applicability is strong, and the product is not easy to shrink and deform.

Specification :

| Grade | Type | Size (mm) | Expandable Rate ( one time ) | Application |

| E grade | E-101 | 1.30-1.60 | 70-90 | Electrical ceramic packaging, fishing boxes, fruit boxes, vegetable boxes, floats, handicrafts, lost foam, etc., suitable for general packaging |

| E-201 | 1.00-1.40 | 60-85 | ||

| E-301 | 0.75-1.10 | 55-75 | ||

| E-401 | 0.50-0.80 | 45-65 | ||

| E-501 | 0.30-0.55 | 35-50 |

Ⅱ.Flame retardant grade EPS raw materials :

F-flame retardant grade has passed the U.S. safety testing laboratory (UL) certification, the document certification number is E360952. F-flame retardant grade should avoid mixing non-flame retardant substances in the processing process, and special attention should be paid to not mixing ordinary EPS. These improper processing methods will reduce the flame retardant performance. The relevant F-flame retardant national standards are: insulated molded polystyrene foam (GB/T10801.1-2002); building materials and products burning performance classification (GB8624-2012). In order to obtain the B2 flame retardant performance, a certain aging time must be given to the molded product to allow the residual foaming agent to escape from the foam body. The aging period is mainly determined by the foaming agent content, apparent density, product size and other conditions In a well-ventilated state, the following empirical data are recommended for sheet products:

15KG/M³ :

20mm thick, at least one week aging period 20mm thick, at least two weeks aging period

30 KG/M³:

50mm thick, at least two weeks aging period 50mm thick, at least three weeks aging period

Product Features:

1. Good flame retardant performance;

2. Fast pre-issue speed;

3. The raw material has uniform particle size and the foamed beads have good fluidity;

4. Wide operating range, suitable for various automatic and manual plate making machines;

5. The foamed beads have fine and uniform cells, and the appearance of the product is smooth and flat;

6. The product has good dimensional stability, good adhesion, good toughness and high strength;

7. The recommended one-time expansion ratio is 35-75 times;

8. Suitable for B2 standard building materials.

Specification:

| Grade | Type | Size (mm) | Expandable Rate ( one time ) | Application |

| F grade | F-101 | 1.30-1.60 | 70-90 | Building materials, thermal insulation and electrical ceramic packaging |

| F-201 | 1.00-1.40 | 60-85 | ||

| F-301 | 0.75-1.10 | 55-75 | ||

| F-401 | 0.50-0.80 | 45-65 | ||

| F-501 | 0.30-0.55 | 35-50 |

Product detail pictures:

Related Product Guide:

We pursue the administration tenet of "Quality is exceptional, Provider is supreme, Name is first", and will sincerely create and share success with all clientele for New Arrival China Raw Polystyrene Beads - EPS raw materials – Xiongye , The product will supply to all over the world, such as: New York, London, Muscat, We take measure at any expense to achieve essentially the most up-to-date equipment and approaches. The packing of nominated brand is our a further distinguishing feature. The items to assure years of trouble-free service has attracted a great deal customers. The solutions are obtainable in improved designs and richer assortment, they're created scientifically of purely raw supplies. It readily available in a variety of designs and specifications for your selection. The most recent kinds are a great deal better than the preceding one particular and they are quite popular with lots of prospects.

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.