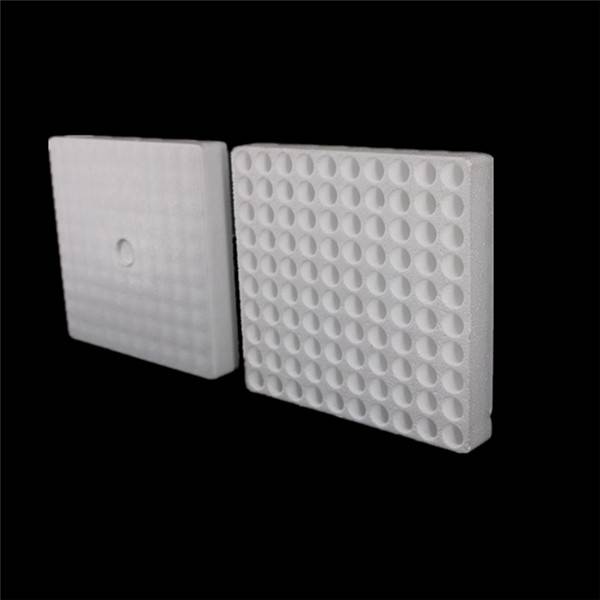

Hot sale Expanded Polystyrene Foam - EPS Foam Packages – Xiongye

Hot sale Expanded Polystyrene Foam - EPS Foam Packages – Xiongye Detail:

EPS – also known as expanded polystyrene – is a lightweight packaging product that is made of expanded polystyrene beads. While it is very light in weight, it is incredibly durable and structurally strong, providing impact resistant cushioning and shock absorption for a wide variety of products made for shipping. EPS foam is an excellent alternative to traditional corrugated packaging materials. EPS foam packaging is used for many industrial, food service, and construction applications, including food packaging, fragile items shipping, computer and television packaging, and product shipping of all types.

Changxing’s protective expanded polystyrene (EPS) foam is the perfect alternative to corrugated and other packaging materials. The versatile nature of EPS foam allows for a vast array of protective packaging uses. Lightweight, yet structurally strong, EPS provides impact resistant cushioning to reduce product damage during transportation, handling, and shipment.

Features:

1. Lightweight. Part of the space of EPS packaging products is replaced by gas, and each cubic decimeter contains 3-6 million independent air-tight bubbles. Therefore, it is several to several tens of times larger than plastic.

2. Shock absorption. When EPS packaging products are subjected to an impact load, the gas in the foam will consume and dissipate the external energy through stagnation and compression. The foam body will gradually terminate the impact load with a small negative acceleration, so it has a better shockproof effect.

3. Thermal insulation. The thermal conductivity is the weighted average of the pure EPS thermal conductivity (108cal/m.h. ℃) and the air thermal conductivity (about 90cal/m.h. ℃).

4. Soundproof function. The sound insulation of EPS products mainly adopts two ways, one is to absorb sound wave energy, reducing reflection and transmission; the other is to eliminate resonance and reduce noise.

5. Corrosion resistance. Except for prolonged exposure to high-energy radiation, the product has no obvious aging phenomenon. It can tolerate many chemicals, such as dilute acid, dilute alkali, methanol, lime, asphalt, etc.

6. Anti-static performance. Because EPS products have low electrical conductivity, they are prone to self-charge during friction, which will not affect general users’ products. For high-precision electronic products, especially large-scale integrated block structural components of modern electrical appliances, anti-static EPS products should be used.

Product detail pictures:

Related Product Guide:

Innovation, excellent and reliability are the core values of our business. These principles today extra than ever form the basis of our success as an internationally active mid-size company for Hot sale Expanded Polystyrene Foam - EPS Foam Packages – Xiongye , The product will supply to all over the world, such as: British, Bolivia, Ghana, Our company is an international supplier on this kind of merchandise. We supply an amazing selection of high-quality merchandise. Our goal is to delight you with our distinctive collection of mindful items while providing value and excellent service. Our mission is simple: To supply the best items and service to our customers at the lowest prices possible.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!