100% Original Styrofoam Cutter Machine - PSF I Type Full Automatic Discontinuous Pre-expander – Xiongye

100% Original Styrofoam Cutter Machine - PSF I Type Full Automatic Discontinuous Pre-expander – Xiongye Detail:

Product Introduction

• Adopting Programmable Logic Controller (PLC), the machine realized automatic material feeding, electronic weighing, temperature controlling and material level control, etc.

• Which can also be set up with density control system according to users’ requirements to realize automatic intelligent production;

• With spiral filling device and electronic weighing device as well as closed foaming barrel and pressure control technology, the machine can sampler continuously so that the foaming pressure is more constant, which greatly improved thermal efficiency and economized steam;

• The machine is composed of famous brand electrical components at home and abroad, pneumatic components, valves, etc. the quality of which are reliable so that ensures precise control on temperature and pressure as well as uniform beading and density of foam material;

• The machine is equipped with fluidized bed dryer which realized drying, automatic sieving, depluming and material conveying to cured silos;

Features

· Chromeplate makes non-adhesion of the bearing.

· The solid bearing is made of heated steel.

· The heating treatment bring the steel a high strength, non-deformation and high resistance to the expansive force from high-density products.

· Foaming density: 4.5-30 kg/m3

· Density tolerance: no more than 3%

Technical Data

| Item | Unit | PSF90 | PSF120 | PSF140II (First, Second Pre-expander) |

PSF160II (First, Second Pre-expander) |

| Barrel Diameter | mm | 900 | 1200 | 1400 | 1600 |

| Effective Volume | m³ | 0.6 | 1.8 | 2.8 | 4.6 |

| Steam Pressure | Mpa | 0.4-0.5 | 0.6-0.8 | 0.4-0.6 | 0.4-0.6 |

| Compressed Air Pressure | Mpa | 0.6-0.8 | 0.6-0.8 | 0.6-0.8 | 0.6-0.8 |

| Production Capacity | Kg/h | 100-400 | 200-1200 | 500-1400 | 500-1600 |

| Foaming Density | Kg/m³ | 8-30 | 8-30

|

4.5-30 | 4.5-30 |

| Density Tolerance | % | ≤3 | ≤3 | ≤3 | ≤3 |

| Installed Power | kw | 4.5 | 17.4 | 21.9 | 34.9 |

| External Dimensions | mm | 1600×1900 x2500 | 3000x1260x3650 | 3450x2100x4500 | 3500x2100x4650 |

| Control Mode | —- | Electronic

computation |

Electronic

computation |

Electronic

computation |

Electronic

computation |

| Drying Way | —- | Fluidized Bed | Fluidized Bed | Fluidized Bed | Fluidized Bed |

| Installed Weight | kg | 1000 | 1750 | 2950 | 3250 |

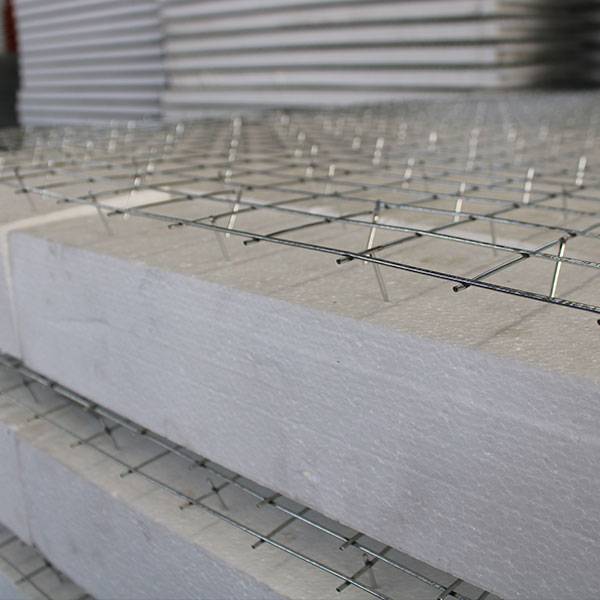

Application

The machine is used for foaming EPS beads. The foamed EPS beads can be widely used for EPS Panel, Box, Insert Block , ICF, Hourdis , Styrofoam Packaging , Helmet , Cornice , Ceiling Board , etc.

Product detail pictures:

Related Product Guide:

As a result of ours specialty and service consciousness, our company has won a good reputation among customers all over the world for 100% Original Styrofoam Cutter Machine - PSF I Type Full Automatic Discontinuous Pre-expander – Xiongye , The product will supply to all over the world, such as: Guyana, panama, Iraq, Our company has already had a lot of top factories and professional technology teams in China, offering the best products, techniques and services to worldwide customers. Honesty is our principle, professional operation is our work, service is our goal, and customers' satisfaction is our future!

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!